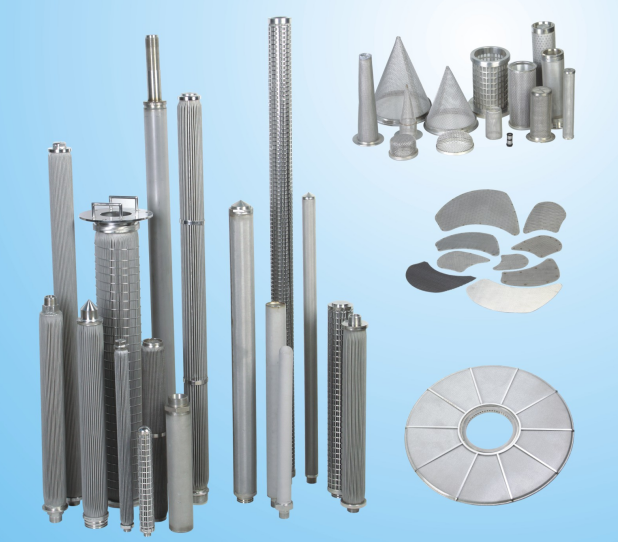

The sintered fiber media replace the fine filtration wire mesh. The process of producing the filter remains the same, but the results and applications are different.

Metallic fiber felt developed by Manfre is made using stainless steel fibers of minimal diameters and varied length; the fibers are dispersed uniformly on an identified surface. Then the process of lapping, lamination, and high-temperature sintering is carried out. other sintered fiber felt media is also availabe, such as Bekeart, Pall,Fuji etc.

Advantages

Multi-layers metallic fiber felt with graded pore sizes formed by layers of different fiber diameters can achieve high filtering accuracy and higher dirt holding capacity.

Metallic thread felt has excellent porosity, due to which the differential pressure is low.

The metallic yarn felt has a high dirt holding capacity, which increases the filter’s stream life and can be used multiple times.

The most important part of the filter element is the welding of the wire mesh ends; the small fibers produce excellent weld quality helping the filter achieve an accurate filtration rating.

Specification of Manfre Sintered Fiber Media

Manfre sintered fibre felt ensures increased product quality and extended polymer candle filter life. All this sums up to higher productivity and lower costs.

Post time: Jan-04-2023